Why Shouldnt Torque To Yield Head Bolts Be Re Used

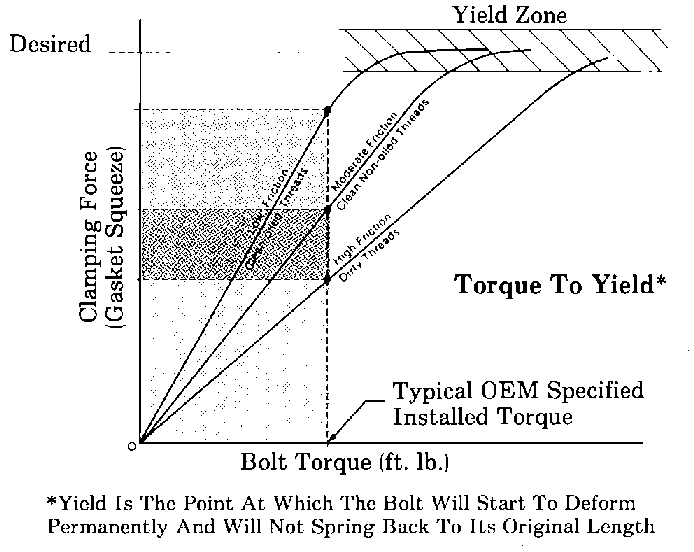

Torque-to-yield (TTY) head bolts are designed to stretch when used. Once stretched, they are not as strong as before. Consequently, they cannot provide the same amount of clamping force and may break or shear off if reused.

Torque-to-yield (TTY) head bolts are designed to stretch when used. Once stretched, they are not as strong as before. Consequently, they cannot provide the same amount of clamping force and may break or shear off if reused.

The TTY bolt-tightening procedure is designed to provide a better, more uniform seal. On the factory assembly line, sophisticated torquing equipment is used to tighten head bolts beyond their yield point. This stretches the bolt slightly and evens out the loading so each bolt provides almost exactly the same amount of clamping force on the head gasket.

Because the tightening procedure permanently stretches the bolts, there is a risk of breakage if reused. Since there is no way to tell how many times such a bolt has been reused, most aftermarket gasket manufacturers say the risks of reusing TTY head bolts far outweigh replacement cost. For that reason, new TTY head bolts are often included in head gasket sets.

Applications where new TTY head bolts are recommended include Chrysler’s 2.2L and 2.5L engines, Ford’s 1.6L and 1.9L Escort engines, General Motor’s 1.8L, 2.0L and 2.5L fours, 3.0L V-6 and 381 diesel V-8.

When new TTY head bolts are installed, a special tightening procedure must be used to achieve proper results. After bolts have been tightened to the recommended torque, each bolt must be given an additional twist. The amount of twist may be 1/4 turn or more, or specified as so many degrees of rotation. Using a simple “torque-to-angle indicator” tool when making the final twist ensures uniform loading and prevents overtightening.