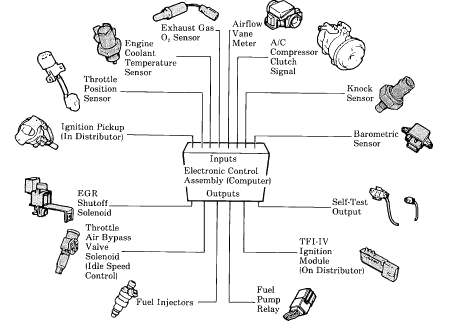

Sensor Map Sensor 02 Sensor Airflow Sensor TPS Knock Sensor Idle solenoid controll coolant temp sensor

Which engine sensors are the most important

All sensors are important. The computer is the brains of a computerized engine control system and sensors are its link to what’s happening under the hood.

Some sensors have more influence on engine performance than others. These include the coolant temperature sensor, oxygen sensor, throttle position sensor, and manifold absolute pressure sensor.

The coolant sensor is often called the master sensor because the computer uses its input to regulate many other functions, including:

Activating and deactivating the Early Fuel Evaporation (EFE) system such as the electric heating grid under carburetor or the thermactor air system.

Open/closed loop feedback control of the air/fuel mixture. The system won’t go into closed loop until the engine is warm.

Start up fuel enrichment on fuel-injected engines, which the computer varies according to whether the engine is warm or cold.

Spark advance and retard. Spark advance is often limited until the engine reaches normal operating temperature.

EGR flow, which is blocked while the engine is cold to improve driveability.

Canister purge, which does not occur until the engine is warm.

Throttle kicker or idle speed.

Transmission torque converter clutch lockup.

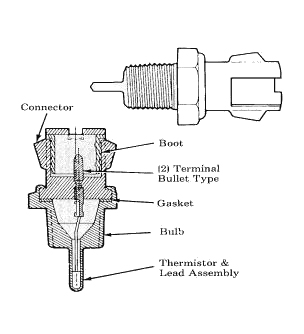

The coolant sensor is usually located on the head or intake manifold where it screws into the water jacket. Sensors come in two basic varieties: variable resistor sensors called thermistors because their electrical resistance changes with temperature, and on/off switches, which work like a conventional temperature sending unit or electric cooling fan thermostat by closing or opening at a preset temperature.

Variable resistor coolant sensors provide the computer with a more accurate indication of actual engine temperature than a simple temperature switch. The computer feeds the sensor a fixed reference voltage of about five volts when the key is on.

The resistance in the sensor is high when cold and drops about 300 ohms for every degree Fahrenheit as the sensor warms up. This alters the return voltage signal back to the computer which the computer then reads to determine engine temperature.

The switch-type sensor may be designed to remain closed within a certain temperature range, or to open only when the engine is warm. Switch-type coolant sensors can be found on GM “T” car minimum function systems, Ford MCU, and Chrysler Lean Burn systems.

Because of the coolant sensor’s central role in triggering many engine functions, a faulty sensor (or sensor circuit) can cause a variety of cold performance problems. The most common symptom is failure of the system to go into closed loop once the engine is warm. Other symptoms include poor cold idle, stalling, cold hesitation or stumble, and/or poor fuel mileage.

The oxygen sensor (O2) measures how much unburned oxygen is in the exhaust. The computer uses this as an indication of how rich or lean the fuel mixture is so adjustments can be made to keep it properly balanced.

A problem with the O2 sensor will prevent the computer from keeping the fuel mixture balanced under changing driving conditions, allowing the mixture to run rich or lean.

The throttle position sensor (TPS) is used with feedback carburetion and electronic fuel injection (EFI) to inform the computer about the rate of throttle opening and relative throttle position. A separate idle switch and/or wide open throttle (WOT) switch may also be used to signal the computer when these throttle positions exist.

The throttle position sensor may be mounted externally on the throttle shaft (the case on most fuel injection throttle bodies), or internally in the carburetor (as in Rochester Varajet, Dualjet and Quadrajet).

The TPS is essentially a variable resistor that changes resistance as the throttle opens. It is the electronic equivalent of a mechanical accelerator pump. By signaling the computer when the throttle opens, the computer enriches the fuel mixture to maintain proper air/fuel ratio.

Initial TPS setting is critical because the voltage signal the computer receives tells it the exact position of the throttle. Initial adjustment must be set as close as possible to factory specs. Most specs are given to the nearest hundredth of a volt.

The classic symptom of a defective or misadjusted TPS is hesitation or stumble during acceleration. The fuel mixture leans out because the computer doesn’t receive the right signal telling it to add fuel as the throttle opens. The oxygen sensor feedback circuit will eventually provide the necessary information, but not quickly enough to prevent the engine from stumbling.

When the sensor is replaced, it must be adjusted to the specified reference voltage. The TPS on most remanufactured carburetors is preset at the factory to an average setting for the majority of applications the carburetor fits. Even so, the TPS should be reset to the specific application upon which it is installed.

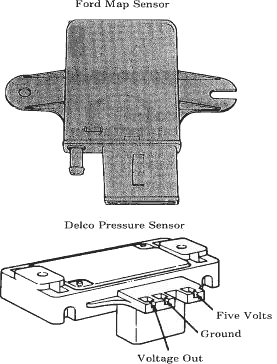

MAP sensor function is to sense air pressure or vacuum in the intake manifold. The computer uses this input as an indication of engine load when adjusting air/fuel mixture and spark timing. Computerized engine control systems that do not use a MAP sensor rely on throttle position and air sensor input to determine engine load.

Under low-load, high-vacuum conditions, the computer leans the fuel mixture and advances spark timing for better fuel economy. Under high-load, low-vacuum conditions (turbo boost, for example), the computer enriches the fuel mixture and retards timing to prevent detonation.

The MAP sensor serves as the electronic equivalent of both a distributor vacuum advance diaphragm and a carburetor power valve.

The MAP sensor reads vacuum and pressure through a hose connected to the intake manifold. A pressure sensitive ceramic or silicon element and electronic circuit in the sensor generates a voltage signal that changes in direct proportion to pressure.

MAP sensors should not be confused with VAC (Vacuum) sensors, DPS (Differential Pressure sensors), or BARO or BP (Barometric Pressure) sensors. A vacuum sensor (same as a differential pressure sensor) reads the difference between manifold vacuum and atmospheric pressure (the difference in air pressure above and below the throttle plate). A VAC sensor is sometimes used instead of a MAP sensor to sense engine load.

A MAP sensor measures manifold air pressure against a precalibrated absolute (reference) pressure. What’s the difference? A vacuum sensor only reads the difference in pressure, not absolute pressure, so it doesn’t take into account changes in barometric (atmospheric) pressure.

A separate BARO sensor is usually needed with a vacuum sensor to compensate for changes in altitude and barometric pressure. Some early Ford EEC-III and EEC-IV systems have a combination barometric pressure/MAP sensor called a BMAP sensor, combining both functions.

Anything interfering with accurate sensor input can upset both fuel mixture and ignition timing. Problems with the MAP sensor itself, grounds or opens in the sensor wiring circuit, and/or vacuum leaks in the intake manifold.

Typical driveability symptoms include detonation due to too much spark advance and a lean fuel ratio, and loss of power and/or fuel economy due to retarded timing and an excessively rich fuel ratio.

A vacuum leak can cause a MAP sensor to indicate low manifold vacuum, causing the computer to think the engine is under more load than it really is. Consequently, timing is retarded and the fuel mixture is enriched.